Plasma methane pyrolysis serving the energy transition

This research, carried out in collaboration with the American company Monolith, is now taking on a new dimension with the signing of a new, even more ambitious framework agreement between the American company and Mines Paris – PSL. It is of major interest today, in view of the necessary transition to a massive decarbonization of energy. This alliance is of paramount importance against a background of the need for massive reductions in CO₂ emissions.

Monolith, founded by two young Silicon Valley entrepreneurs in 2012, quickly became interested in gas pyrolysis for carbon and hydrogen production. Looking for expert partners, they turned to the teams at Mines Paris – PSL, one of only two teams in the world – along with a Norwegian team – to have been working on this disruptive technology for around twenty years. This collaboration led to the signature of an initial framework agreement and several successive contracts, which have accompanied Monolith’s rise to prominence in the United States, where the process is now in the industrial development phase. This alliance is of vital importance against a backdrop of the need for massive reductions in CO₂ emissions.

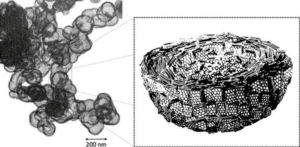

Transmission electron microscopy (TEM) image of a characteristic carbon black aggregate and schematic representation of the cross-section of a primary particle (after Donnet [1]).

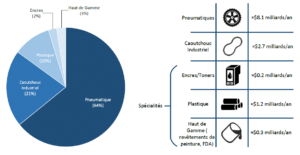

The process developed is based on thermal plasma pyrolysis of methane, where the latter is subjected to very high temperatures, breaking down the molecule to produce nanostructured solid carbon and hydrogen gas. This co-production offers major economic opportunities, as black carbon (one of the 50 most important chemicals in the world) is used in a variety of high value-added industrial applications: tires, technical polymers, batteries… Hydrogen can be used in the chemical industry – notably for ammonia production – or as a clean energy carrier. This new process represents a decisive step towards the production of carbon-free hydrogen at production costs of around $2 per kg.

Main carbon black applications represented by sector sales (worldwide production: 12 million tonnes per year).

While the favorable legislative context in the United States, with the entry into force of the Inflation Reduction Act recently passed at the instigation of President Joe Biden, and the abundance of natural gas resources favor the rapid development of this technology, Europe faces different challenges. Despite the geopolitical upheavals linked to the war between Russia and Ukraine and tensions in the supply of natural gas, the rapid development of biogas, the climate emergency and the need to decarbonize energy all place hydrogen at the heart of the world’s energy challenges, and could provide fertile ground for the deployment of this technology in Europe.

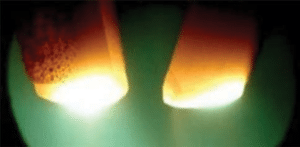

View of plasma zone: electrodes (photo ©Laurent Fulcheri).

Faced with pressing environmental challenges and the imperatives of reducing CO₂ emissions, “turquoise” hydrogen is emerging as a promising alternative. By offering an intermediate route between traditional CO₂-emitting production methods and emerging solutions such as energy-intensive water electrolysis, gas pyrolysis opens up new prospects for a sustainable energy transition. This partnership between Mines Paris – PSL and Monolith symbolizes a giant step towards a cleaner, more efficient and sustainable energy future.

After completing a thesis at the CNRS, Laurent Fulcheri joined the École in 1989, where he set up a new research team on “Plasma Processes” within CENERG, now the PERSEE Center, a major player in the energy and ecological transition. A research director at Mines Paris – PSL, he has for many years been studying the plasma pyrolysis of natural gas at very high temperatures for the co-production of hydrogen and carbon blacks, in collaboration with the American company Monolith.

The PERSEE Center at Mines Paris-PSL is a member of Carnot M.I.N.E.S. The label, created in 2006, is a mark of excellence awarded by the French Ministry of Higher Education and Research to research establishments in France. It is designed to encourage partnership research, i.e. research carried out by public laboratories in partnership with companies. These institutes promote the transition from research to innovation, and increase technology transfer to economic players.

[1] Donnet JB, Bansal RP,Wang MJ. In : Carbon Black, Science and Technology, 2e édition, New York : Marcel Dekker, 1993.

The strengthening of the collaboration between the American industrialist and the French higher education and research establishment, initiated in 201...