Decarbonizing industry: Monolith and Mines Paris – PSL renew their research partnership and sign a memorandum of understanding to develop thermal plasma processes.

Monolith, a world leader in the production of carbon black and hydrogen with lowCO2 emissions, and Mines Paris – PSL, France’s leading engineering school by volume of contract research, announce the strengthening and expansion of the framework agreement governing their collaboration until February 2030, in order to support the R&D efforts conducted within the Centre Procédés, Energies Renouvelables et Systèmes Energétiques (PERSEE) of Mines Paris-PSL, in Sophia Antipolis.

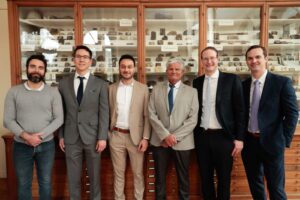

On Wednesday April 24 at the Musée de Minéralogie, Rob Hanson, co-founder and CEO of Monolith Materials, and Vincent Laflèche, Managing Director of Mines Paris – PSL, renewed their partnership to develop thermal plasma processes for industrial decarbonization.

The signing was introduced by a keynote address from Laurent Fulcheri, Director of Research at the PERSEE Center of Mines Paris-PSL, whose work on methane pyrolysis for the production of decarbonated hydrogen and solid carbon is at the origin of Monolith’s activities.

Monolith and Mines Paris-PSL first joined forces in 2012, focusing on technical plasma technologies and processes resulting from research directed by Professor Laurent Fulcheri.

Monolith and Mines Paris-PSL are thus building on the successes achieved over the past 10 years to pursue the development of innovative research and explore new applications for thermal plasmas, in order to continue stimulating innovation in the context of industrial decarbonization.

“Mines Paris has been an outstanding partner in our development, working alongside our teams to discover and deploy the most advanced technologies,” said Rob Hanson, co-founder and CEO of Monolith. “Through this expanded relationship, our customers will have the opportunity to see first-hand the transformative research the Mines Paris team is conducting, enabling them to collaborate and explore new ways to use low-emission carbon black to make cleaner everyday products.“

Back in 2012, Monolith established a partnership with Mines Paris to leverage the expertise of the Centre Procédés, Energies Renouvelables et Systèmes Energétiques (PERSEE) in the field of thermal plasma processes. Over the past twelve years, Mines Paris has led high-impact research and development programs to develop, with Monolith, a disruptive methane pyrolysis process for the production of carbon black and turquoise hydrogen.

By updating this partnership agreement, Monolith is accelerating innovation on an international scale, and creating new opportunities for its customers in numerous industrial sectors.

As a result of the negotiations, Monolith and Mines Paris-PSL have signed a letter of intent to set up a joint research facility in France within the next 3 years, at the Sophia Antipolis site of Mines Paris-PSL. Monolith, which will set up a subsidiary in France, thus confirms its desire to make Mines Paris its preferred research partner for its development. The new agreement paves the way for Monolith to develop new research capacities in order to respond to French and European calls for projects, as well as to develop research projects with Monolith’s industrial partners. Under the new agreement, Mines Paris-PSL will have the right of first refusal on projects by Monolith and its partners in France and Europe.

Furthermore, and in a rather innovative move, the agreement provides for the allocation of shares in Monolith to Mines Paris-PSL, which will hold them through Armines, its value-adding structure.

For Vincent Laflèche, Managing Director of Mines Paris – PSL, ” this partnership is emblematic of the commitment of research at Mines Paris – PSL to supporting companies in the transition to a carbon-neutral world. It is also an illustration of the entrepreneurial spirit that has animated the School since its creation, and which is embodied here in an exemplary industrial success story. I am delighted by this collaboration with Monolith, which will enable us to meet the research challenges and needs of French and European industry “.

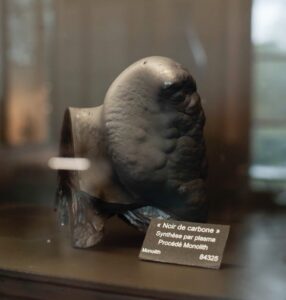

Carbon black is one of the fifty most important chemicals. It is present in many everyday products, from tires and paint to batteries and electronics, but its traditional production generates high levels ofCO2 emissions. Monolith’s plasma pyrolysis process, designed and perfected with Mines Paris, uses renewable electricity to convert renewable natural gas into carbon black and other materials, modernizing an age-old process. Monolith’s first-of-its-kind innovation generates virtually no local emissions.

This announcement follows Monolith’s partnership with The Goodyear Tire & Rubber Company to use Monolith’s own carbon black in the tread formulation of selected tires. Supported by research at Mines Paris, the carbon black product resulted in the first use of low-emission carbon black in tire manufacturing. Headquartered in Lincoln, Nebraska, Monolith currently operates its commercial-scale production plant in Hallam, Nebraska, and has offices and R&D facilities in San Carlos, California, Denver, Colorado, and Kansas City, Kansas.

While the first generation of processes focuses on the co-production of high-value-added carbon blacks and decarbonated hydrogen known as “Turquoise”, which enables a highly favorable economic model, the partners are already working on second-generation processes for the production of decarbonated turquoise hydrogen. This will raise the question of how to use solid carbon with lower added value on a very large scale. Several avenues are already being explored.

The development of this new plasma process has had a resounding impact on high-temperature industrial processes – traditionally based on hydrocarbon combustion. It marks the start of a new era in the decarbonization of industry, and paves the way for many more plasma processes which – I’m convinced – will be developed in the years to come.

Laurent Fulcheri

Research at Mines Paris – PSL has been focusing for many years on the study of plasma pyrolysis of natural gas at very high temperatures for the co-pr...