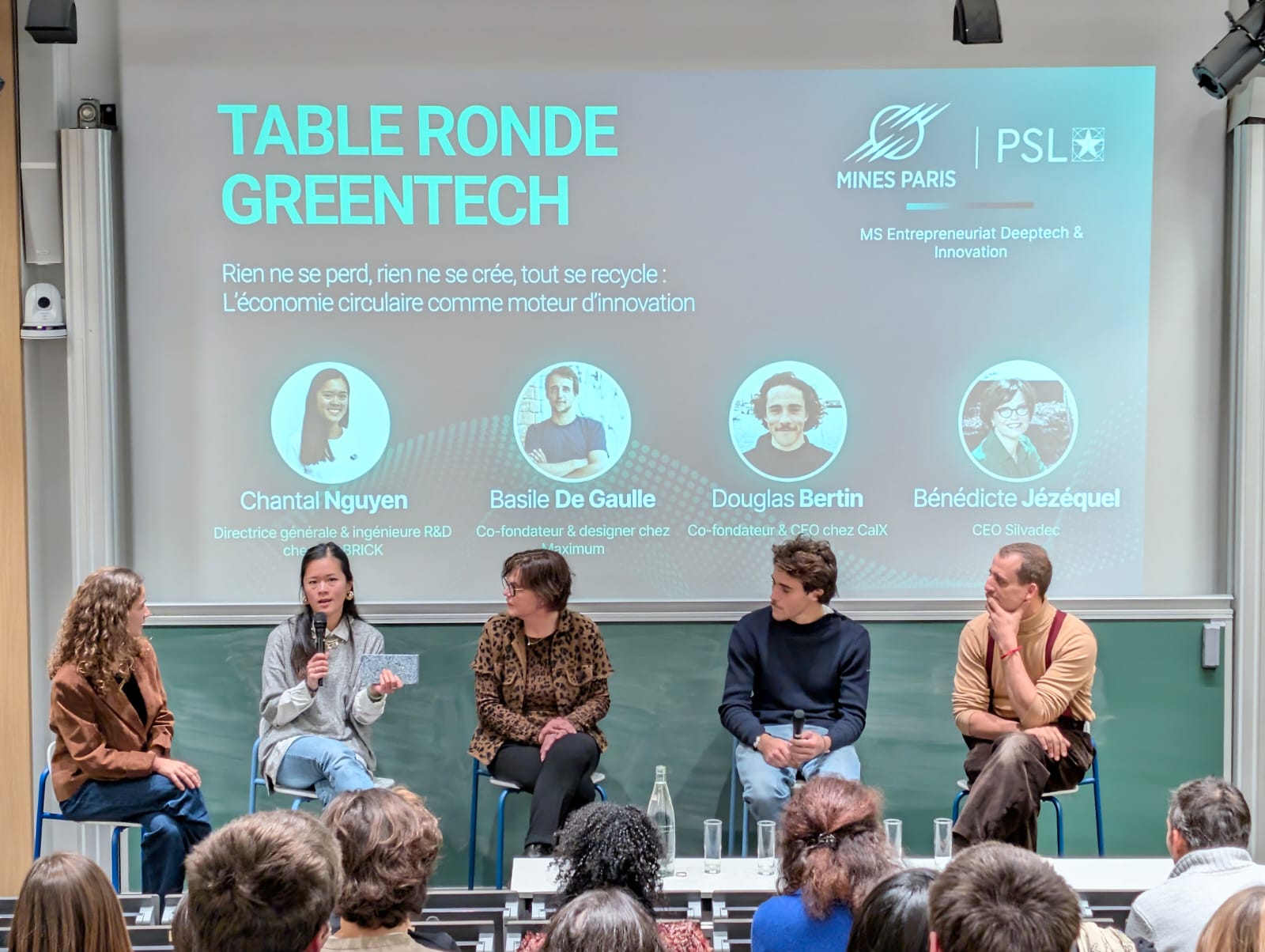

Recycling polymers and composites differently: the challenge taken up by the CYCLADES chair

The creation of the CYCLADES chair is part of a coherent and committed scientific trajectory at Mines Paris – PSL. As CEMEF celebrates its 50th anniversary in Sophia Antipolis, Elie Hachem, director of the center, points out that the chair appears to be a new catalyst for partnerships and scientific investment.

Recycling is above all a shaping process. This chair is not an isolated project: it is part of a structured strategy based on modeling, experimentation, and now artificial intelligence.

Élie Hachem, Director of the Center for Material Shaping (CEMEF) at Mines Paris – PSL

The first chair dedicated to recycling at CEMEF, CYCLADES is also the center’s seventh industrial chair. It is part of a drive to strengthen experimental resources, ramp up scientific computing, and open up new fields of application, combining mathematics, physics, mechanics, and materials science.

Closely linking theoretical studies and practical applications, research at Mines Paris – PSL is demanding, rooted in industrial issues, and fundamentally multidisciplinary. For Paolo Stringari, Director of Research at the School, the CYCLADES chair fully embodies this orientation.

At Mines Paris – PSL, we embrace what some call “flaws”: research focused on concrete issues and a strong multidisciplinary approach. It is precisely these characteristics that enable us to tackle complex issues such as the recycling of polymers and composites.

Paolo Stringari, Director of Research at Mines Paris – PSL

The ABSOLU project, presented by Nathanaël Guigo, illustrates the research challenges addressed by Mines Paris – PSL in the areas of recycling and the circular economy. By developing innovative processes to obtain high-quality recycled materials, the project is fully in line with the School’s strategic objectives for a more circular and sustainable industry.

The chair is thus at the heart of the strategic priorities of our PSL University for the coming years, particularly those related to the environment, adaptation to climate change, resource sovereignty, and low-carbon processes. Material recycling is becoming a key lever in supporting the transformation of industrial value chains at the European level.

As the chair’s main partner, IPC plays a structuring role in this initiative. Its CEO, Luc Uytterhaeghe, highlighted the unique mission of the Industrial Technical Centers (CTI), which serve a network composed mainly of SMEs.

⬅️ Image on the left: an example of an innovative approach to recycling developed by Nathanaël Guigo, involving the dissolution of materials in a solvent.

Plastics processing is a subcontracting industry, with an average company size of less than 40 employees. The CYCLADES chair is essential for transforming scientific knowledge into concrete industrial solutions.

Luc Uytterhaeghe, Managing Director of IPC

Recycling, reuse, polymer purification, substance analysis, additive manufacturing, composites… Thanks to its technology platforms spread across the country, IPC is positioned as a key player in technology transfer.

The chair creates partnerships with numerous players in the field. Joost Schollaert, Deputy CEO of Galloo Plastics, shared his company’s expertise in recycling plastics from end-of-life vehicles (ELVs). The company processes 90,000 tons of ELVs per year, producing recycled polypropylene pellets for the automotive industry. Their process, from depollution to advanced sorting, ensures quality that complies with current regulations.

The chair is fully in line with its partners’ strategy of building a robust knowledge base, which is essential for European competitiveness and industrial sovereignty.

Latest-generation sorting machine from the IPC pilot line for evaluating sortability.

Jointly led by Jean-Luc Bouvard and Christelle Combeaud for CEMEF, and by Gilles Dennler, Ronan Le Goff, and Skander Mani for IPC, the CYCLADES chair aims to overcome several major scientific obstacles related to the integration of recycled raw materials.

At the heart of the program is a detailed understanding of the links between forming processes, microstructure development, and the final properties of materials. The challenge is to control the high variability of recycled materials, namely thermal, rheological, and mechanical properties, in order to guarantee quality, performance, and safety in industrial applications.

AI is becoming a key tool in this area for qualifying variability, identifying dominant physical parameters, and developing robust predictive models.

Jean-Luc Bouvard, lecturer-researcher at CEMEF and co-holder of the chair

For Ronan Le Goff and Skander Mani, scientific managers at IPC, the objective is clear: to better control the variability that affects the quality of products made from recycled plastics (MPR). Drawing on technological platforms, this work translates into concrete projects carried out with manufacturers, from the eco-design of packaging to the development of solutions for the automotive industry.

Two theses were already launched in October 2025: the first, presented by Barthélémy Levasseur, focuses on understanding and predicting the evolution of the mechanical properties of recycled plastics; the second, presented by Luis Reichwald, studies the impact of using recycled carbon fibers on the mechanical behavior and lifespan of thermoplastic composites. The chair’s target areas, which include the automotive, aeronautics, and packaging industries, perfectly illustrate its cross-disciplinary ambition.

Experimental methods for microstructural analysis of polymers: dimensional stability under temperature.

The CYCLADES chair also draws on the expertise of the Institut Carnot M.I.N.E.S, which plays a key role in bringing together skills and funding collaborative projects. It contributes to the scientific renewal of the sector through theses, exploratory research projects, and synergies between academic laboratories and industrial platforms.

Doctoral students, who are fully integrated into the program, embody this link between long-term research and immediate industrial challenges. Their presence underscores the chair’s ambition: to train a new generation of researchers capable of thinking simultaneously about materials, processes, data, and sustainability.

By bringing together high-level academic research, industrial expertise, and advanced digital tools, the CYCLADES chair is positioned as a strategic lever to support the transformation of plastics and composites. Beyond scientific advances, it contributes to a broader reflection on industrial resilience, European competitiveness, and the transition to more sustainable production models.

Recycling is not just a regulatory constraint: it is a major field of innovation.

Christelle Combeaud, lecturer-researcher at CEMEF and co-leader of the chair

With CYCLADES, Mines Paris – PSL and the IPC are affirming a common ambition: to make the recycling of polymers and composites a field of scientific excellence and a driver of industrial transformation.

Recycled materials, industrialized processes, environmental regulations, and economic profitability: how can waste be transformed into a certified and...