AI from data to matter: at CMAT, predicting and optimizing the materials of the future

Modern materials, such as metal alloys, composites, and recycled polymers, have complex microstructures consisting of grains, fibers, pores, and defects that are invisible to the naked eye. However, it is precisely these microscopic details that determine mechanical strength, fatigue life, and the risk of cracking.

Traditionally, the study of these phenomena has relied on complex physical models, the development and calibration of which requires lengthy, cumbersome, and costly experimental campaigns. Conventional mechanical tests, such as fatigue or tensile tests, require significant resources and do not allow for the exhaustive exploration of all possible configurations.

In this context, AI opens up new possibilities: by drawing on ever-increasing amounts of data while strictly adhering to the laws of physics, it makes it possible to reduce the number of tests, speed up analysis, and more effectively target the parameters that are most decisive for material behavior.

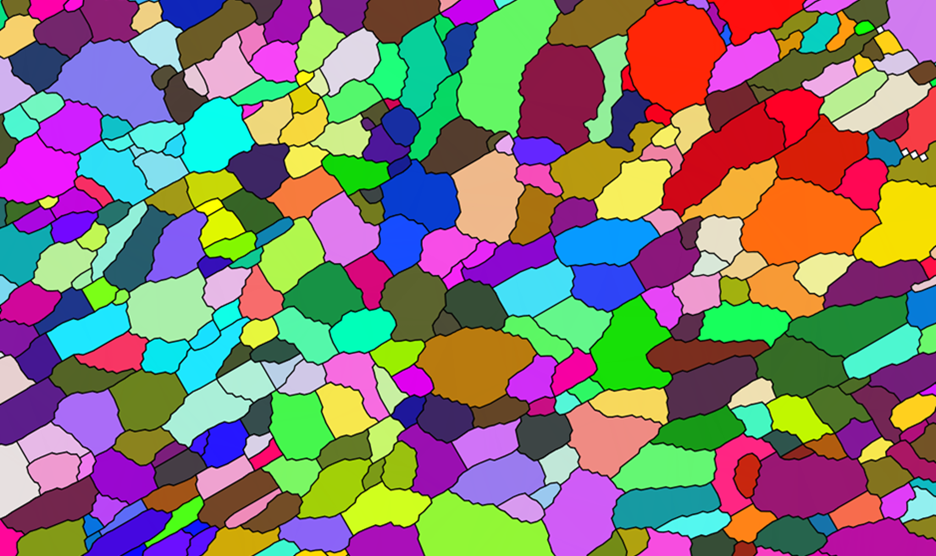

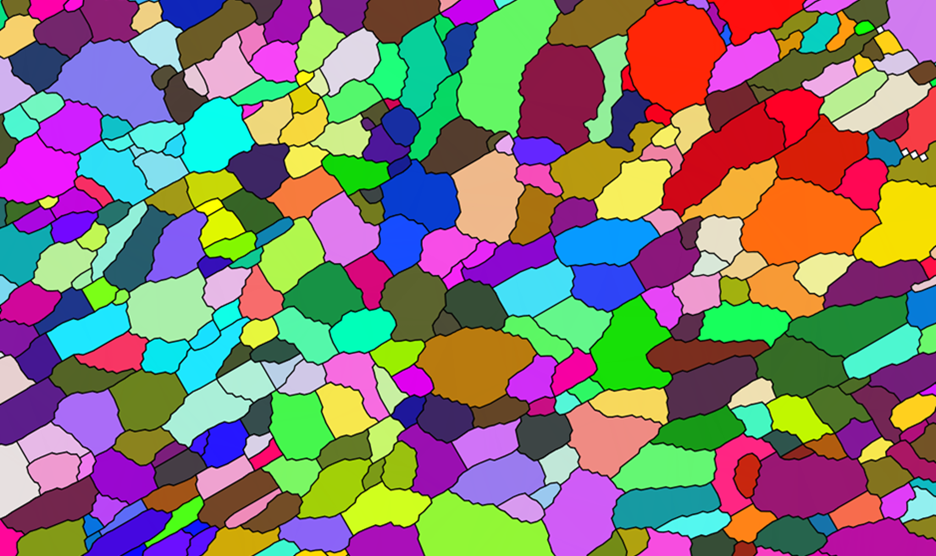

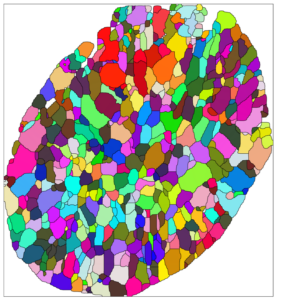

Active material particle constituting the positive electrode of NMC-type lithium-ion batteries, used for example in electric cars and phones. The sample was prepared by ion beam in a very powerful scanning electron microscope capable of seeing the internal organization of the material, then characterized by EBSD. The colors correspond to different crystal orientations, which do not all behave in the same way during the battery’s charge and discharge cycle. Analyzing the arrangement and orientation of these crystals makes it possible to perform realistic multiphysics simulations, i.e., to create highly realistic digital models to better understand what happens inside the battery during operation, providing a better understanding of the mechanisms involved in battery cycling and paving the way for improvements in battery performance and lifespan.

Authors: Clémence Pinot (CMAT), Jean-Michel Scherer (CMAT), Cyrille Colin (CEMEF), Fabrice Gaslain, Domitille Giaume (Chimie ParisTech – PSL), Aubin Geoffre (CMAT), Cécilie Duhamel (CMAT)

A first major area of research concerns the automated processing of experimental data, in particular images from X-ray tomography, a non-destructive technique that allows the reconstruction of “cross-sectional” images of a three-dimensional object, microscopy, or electron backscatter diffraction (EBSD – EBSD), a technique that maps the orientation of crystals within a material in order to understand its internal structure and mechanical behavior.

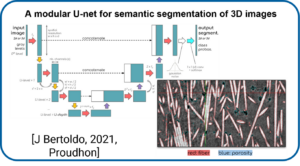

Using specialized neural networks, CMAT researchers are developing tools capable of:

For example, U-Net-type architectures, a symmetrical U-shaped architecture that allows for accurate image segmentation while preserving important contextual details, now achieve greater accuracy than a human expert, while drastically reducing analysis time. Furthermore, advanced models such as Vision Transformers are capable of capturing both local and global information, which is essential for understanding the mechanical behavior of a material under stress.

These tools pave the way for faster, more detailed, and more systematic characterization of industrial materials.

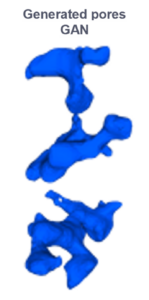

Another major scientific obstacle is access to representative data, particularly when it comes to rare but critical defects. To address this, CMAT uses generative models, in particular GANs (Generative Adversarial Networks) and diffusion models.

These AIs are capable of artificially generating realistic 3D microstructures, incorporating:

These synthetic microstructures are then used in numerical simulations to study the influence of defects on fatigue or fracture, without multiplying destructive tests.

Above all, AI-generated microstructures provide a better representation of the diversity and criticality of defects observed in real-world conditions. They can therefore be used to quantify the impact of these defects on the service life of materials more reliably, extract robust statistics, and develop new control and prediction tools. The goal is not to artificially over-optimize performance, but rather to avoid excessively conservative safety margins by relying on a more detailed and realistic understanding of material behavior.

The impact is reflected in a massive reduction in the number of physical tests and accelerated exploration of new materials.

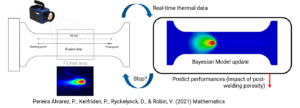

Detailed physical simulations often rely on calculations that can take hours or even days. To make them usable in an industrial context, CMAT is developing AI-augmented digital twins.

The principle:

This approach is particularly applicable to processes such as welding, where thermal cameras provide real-time data. AI can then instantly estimate the internal stresses in the material and anticipate the risk of cracking.

This work provides decision-making tools that can be used directly in industrial production.

Unlike purely “black box” AI, the CMAT approach is based on a close hybridization between data and physical laws. Neural networks do not replace physics: they complement the areas of uncertainty in existing models.

In concrete terms:

This strategy preserves interpretability, robustness, and scientific credibility, which are essential for industrial adoption.

This work was presented at the ITN AI Workshop, held on December 10, 2025, at Mines Paris – PSL. Designed as a space for cross-disciplinary exchange, the event brought together researchers, teachers, and doctoral students to discuss the concrete uses of AI in research. At CMAT, this dynamic is fully in line with the School’s structural projects in the fields of additive manufacturing, energy, mobility, and industrial partnerships.

Beyond the diversity of topics, the workshop highlighted a common dynamic: building AI that is rooted in reality, capable of interacting with humans and integrating into complex systems.

Through this research, CMAT shows that AI can become a true scientific tool, serving more efficient, faster, and more reliable engineering.

By combining experimentation, physical modeling, and AI, CMAT is contributing to a profound transformation in materials science: better understanding for better design, while responding to contemporary industrial and environmental challenges.

How can artificial intelligence (AI) be turned into something more than just a powerful tool? At the Center for Scientific Management (CGS) at Mines P...