Reindustrialization, decarbonization… We shouldn’t forget mid-sized companies

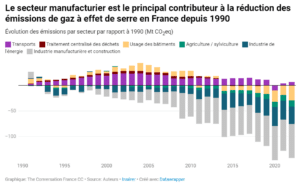

How has France managed to decarbonize so far? Of the 136 million tonnes of CO2 equivalent saved between 1990 and 2022, 66 million, or almost half, came from a reduction in manufacturing industry emissions.

This decline contrasts sharply with the trend in global industrial emissions, which jumped by 64% between 2000 and 2022. Several factors explain this divergence in trajectories, and not all of them are necessarily positive for the environment. Attempting to identify them, as we do in our report “Decarbonization, Reindustrialization & Mid-Sized Companies”, provides some keys to thinking about the next steps in this global movement to reduce air pollution.

While reducing production emissions is a necessity, the more fundamental question is the real carbon footprint of our way of life. When decarbonizing means importing more, the French footprint is inflated by the carbon content of production in less environmentally virtuous economies. However, measuring local emissions alone does not take into account imported content. In this case, apparent decarbonization may actually be accompanied by a worsening of the environmental problem.

Conversely, exporting more virtuous products to Europe, thanks to more decarbonized energy, would be a guarantee of overall emissions reduction, perhaps at the cost of less limited emissions for the Old Continent. The challenge of green reindustrialization is to reduce our trade deficit while cutting overall emissions. Today, however, we’re a long way from achieving this.

If French industry has reduced its emissions since the signing of the Kyoto Protocol, this is partly because it has seen a reduction in its manufacturing output over the period (-11% between 2006 and 2022), in contrast to other economies, notably in Asia (+124% between 2006 and 2022), which have developed strongly.

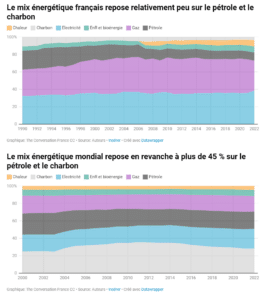

French industry has also been able to decarbonize its production by relying on a better energy mix using less and less oil and coal, a more positive signal. It has also benefited from breakthrough innovations, particularly in the chemical industry, which has radically reduced nitrous oxide emissions in the manufacture of adipic acid, nitric acid and glyoxylic acid. Such pleasant surprises are rare, however, and the next breakthrough innovations that could bring about such reductions are not yet known.

To support the decarbonization effort, the European Union has launched the fit for 55 package. French public policy, on the other hand, focuses mainly on the 50 highest-emitting sites, the famous top 50. The objective set by the French President on November 8, 2022 is to halve French industrial emissions from the fifty most polluting sites over the next decade, with 54 billion euros on the table to support the movement. At the end of January, French Prime Minister Gabriel Attal announced a similar initiative aimed at the 50 sites that put the most plastic packaging on the market.

Admittedly, these sites alone account for almost 60% of industrial emissions and are undeniably a prime target for decarbonization. What’s more, they are mainly active in the metallurgy, building materials and chemicals sectors. These sites produce the “simple” goods needed to manufacture more complex industrial goods. Decarbonizing these sites will therefore have a direct impact on their emissions, but also an indirect impact on other sectors. Supporting the efforts of these sites also helps to keep them in the area, which is a question of sovereignty that also legitimizes such intervention.

The focus on the 50 highest-emitting sites should not, however, cause the rest of industry to fly under the radar, even though it accounts for 40% of industrial emissions, the bulk of employment in the sector and the keystone of the country’s potential green reindustrialization. Unlike the 50 highest-emitting sites, this diffuse industry extends over a large number of sectors and across the whole country. Given the sheer number of companies involved, it’s hard to imagine engaging in a one-to-one dialogue with each and every one of them: the public authorities don’t seem to be able to use the same recipe as the 50 sites.

So how do we go about it?

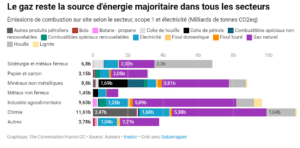

To grasp the problem of decarbonizing diffuse industry, it’s important to remember that there are two types of emissions: “process” emissions and “combustion” emissions. Process” emissions are inherent to the chemical reaction required for production. For example, cement production involves heating a mixture of limestone, clay and sand to very high temperatures, releasing greenhouse gases. Combustion” emissions, on the other hand, come from the energy used to enable combustion. For example, blast furnaces in the steel industry use coal, which emits greenhouse gases as it burns.

Decarbonizing “processes” is above all a problem of innovation. To reduce these emissions, we need to invent a new way of producing, or use a different chemical reaction that emits fewer greenhouse gases. Solutions have already been discovered, such as cement without clinker, which is produced cold and consumes less energy, while others are under development.

To reduce “combustion” emissions, we need to replace one energy source with another that emits fewer emissions, e.g. replacing a gas furnace with an electric one, or substituting an electric motor for an oil-fired one. It is these “combustion” savings that seem to be the most accessible in the diffuse economy. Manufacturing industry has already switched from the most emissive fossil fuels to gas, which is the predominant energy source in all sectors except ferrous metallurgy, which is structurally based on the use of coal. Reducing emissions from diffuse industry will require a major electrification effort.

The keys to success seem to lie with the public authorities and the companies themselves. The role of public authorities is to inform and support, taking maximum account of sectoral and local particularities. The NOTRe law of August 7, 2015, which gives the region responsibility for economic and sustainable development, can be an important vector for success, as can the development of territorialized industrial policies, if it is given sufficient resources. The abolition of the value-added contribution (CVAE), by reducing the independence of local authorities, is not a step in this direction.

Companies, for their part, can facilitate decarbonization by cooperating and sharing experience. The creation of a network is the surest and quickest way to encourage the spread of best practices and the reproduction of solutions that work.

Let’s bet that French industry could be exemplary in this respect, thanks to the electrification of industry, which represents the next pocket of emissions reduction to be exploited. It’s also thanks to a high-quality workforce, and thanks to a network of national and regional public policies that could make massive use of local cooperation and experimentation in a diffuse industrial fabric made up of companies that are smaller and less well known than the large ones, which are in the majority in the top 50, but nonetheless predominant in industrial employment. Killing three birds with one stone…

Authors

Photo: ArcelorMittal’s Dunkirk site is one of the production sites targeted by the 50-site policy. Source and credit: Arcelor-Mittal/SP – Franck CRUSIAUX/REA FOR “LE POINT”.