Mines Paris – PSL is one of three winners of the Ile de France 2030 Region’s SESAME project call.

The SESAME program aims to support research by providing the material resources needed to develop new projects and maintain cutting-edge technologies. For this new session, 5 million euros in subsidies from the State and the Region have been awarded to 3 ambitious projects, including 1 million to Mines Paris – PSL for its EPROM project. The project concerns laser-wire metal additive manufacturing, the first of its kind on an industrial scale in the Paris Region, coupled with a health-materials approach for the manufacture of high value-added parts.

This new investment is a logical continuation of Mines Paris – PSL’ efforts in the field of Metal Additive Manufacturing.

Jean-Dominique BARTOUT, Head of Elaboration Processes and Materials Platform

The winners of wave 4 of the SESAME Filières France 2030 call for projects were announced at an event organized by the Region on March 19, 2024, to celebrate 30 years of regional investment in scientific facilities. Photo credit: © Région Île-de-France/Hugues-Marie Duclos

Bi-Laser additive manufacturing machine

Supported by the Centre des Matériaux of Mines Paris – PSL, the EPROM 2025 project aims to provide companies in the Ile-de-France region with an R&D, innovation and training platform incorporating the main metal additive manufacturing technologies.

EPROM 2025 will complement and strengthen the existing metal additive manufacturing (AM) offering in the Ile-de-France region by acquiring an industrial-scale manufacturing cell featuring Wire Laser Additive Manufacturing (WLAM) technology. These capabilities will enable the production of structural parts with optimized material health, whose characteristics will fall between those achieved by Laser-Powder Bed Fusion and Wire Arc Additive Manufacturing.

EPROM 2025 will boost the competitiveness of companies, including SMEs and ETIs, by enabling them to carry out demonstrations, establish the cost structure of their FA project by integrating the material health/manufacturing cost issue, train their staff in the full range of Mproc2étallique FA technologies, and carry out R&D activities. EPROM 2025 will increase and strengthen collaborations between companies and academic players.

The EPROM platform will be located on the new Versailles Satory site, in specially adapted premises, and will be open to companies for up to 30% of the machine park time.

Real-time L-PBF process control for the material health of manufactured parts

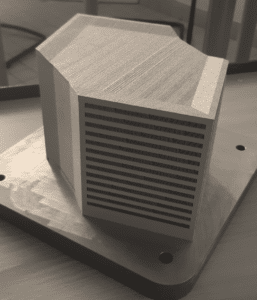

Gas-to-gas heat exchanger made by FA

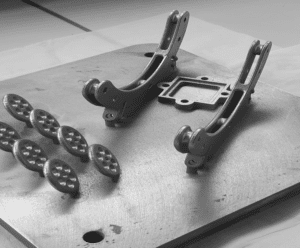

Refractory metal prototyping of heat treatment (HT) furnace components

The Materials Centre aims to provide the regional and national industrial fabric with a research, innovation and training environment incorporating the main FA technologies, including SLM, MBJ and Cold Spray facilities enhanced by a WLAM (Wire Laser Additive Manufacturing) machine for the production of industrial-scale parts by :

Centre des Matériaux of Mines Paris – PSL.

The platform’s missions will be to :

The project will capitalize on the FA equipment already available at the Centre des Matériaux and on the latter’s know-how in its implementation. Resourcing and development will be fuelled by the research carried out by the Materials Centre and by specific requests from partners accessing the platform.

“Our experimental activities began at the Centre des Matériaux in 2008, and the machine park has been steadily expanded. The creation of a technology platform on the Versailles Satory site, open to the world of industry, in particular SMEs and ETIs, represents a new way of approaching our partnerships and extending our collaborations beyond the circle of our historical interlocutors, both industrial and academic. The core business of the Centre des Matériaux remains the triptych materials-health-materials-durability. Our know-how in the development of observation and characterization tools for materials and parts produced by FA, developed on industrial-scale machines, is a precious asset and enables us to increase our research activity in the field of high value-added materials and structural parts.” Jean-Dominique BARTOUT, Head of the Elaboration Processes and Materials Platform and scientific leader of the project.