[LOW-TECH] UNDERSOLAR engineering project: a solar furnace for the Biot glassworks

At a time when environmental and energy issues are taking center stage, Mines Paris – PSL, with its work at the Centre de Mise en Forme des Matériaux (CEMEF) and the Centre de Recherche O.I.E (Observation, Impacts, Énergie), is actively involved in the search for sustainable solutions. The low-tech approach, advocating simple, accessible technologies, is emerging as an ecological response to the depletion of fossil fuels and climate change. The design of a concentrated solar furnace, carried out by the students and developed in collaboration with craftsmen from the Verrerie de Biot glassworks, illustrates the application of these low-tech principles.

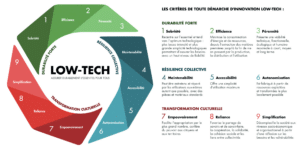

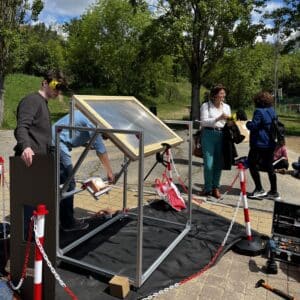

Installation of the Lytefire concentration furnace used by Aurinko for solar roasting.

Low-tech emerged in the 1960s and 1970s as a response to the problem of how to deal ecologically with the depletion of fossil fuels and climate change.

Contrary to the widespread view that high-tech is the salvation solution, notably by promoting denser use of electricity, proponents of low-tech advocate the adoption of simpler, more sustainable technologies.

Low-tech can be seen as a movement: there are thinkers (Bihouix, Illich, Schumacher), but no single definition brings everyone into agreement. The research carried out at the École approached the definition given by Carrey and Lachaize, according to which “a technology is low-tech if it constitutes an elementary technical brick of a perennial, equitable and convivial society”. Here, the idea is to form a society, or a whole, that is low-tech, and not just useful small-scale innovations.

However, low-tech should not be seen as the antithesis of high-tech. In fact, it’s not necessarily relevant to categorize an object as low-tech. It’s more a question of approach: if the idea is to find a low-tech alternative to a current solution, we’ll have to find one that’s more low-tech than the current one. This is sometimes referred to as techno-discernment: you can use technology, but only if it’s the best choice for meeting an identified need.

Following the observation of the combined needs of the craftsmen of the Biot glassworks and those of the CEMEF researchers at Mines Paris – PSL, a project for a low-tech concentrated solar furnace was born. This engineering project, carried out by students in the second year of the Civil Engineering Cycle, as part of the UE31/41 UNDERSOLAR teaching unit, has been led by the O.I.E (Observation, Impacts, Energy) Research Center since March 6. This collaboration with local glassmakers underscores the promising potential of this application, offering a concrete response to contemporary energy and environmental challenges.

“In the context of our project, the notion of techno-discernment is very important. We set out to propose a more low-tech alternative to glass melting than those currently used (electric or gas furnaces), but without falling into the “system D”: we bought technology, the lens is a rather complex object … For us, the low-tech approach is a transition between our current technologies, which are complex, polluting and unsustainable, and those of a future where we would use objects that are sober, repairable and that enable conviviality and equity.” Philippe Blanc, Research Director, Centre O.I.E.

“In the context of our project, the notion of techno-discernment is very important. We set out to propose a more low-tech alternative to glass melting than those currently used (electric or gas furnaces), but without falling into the “system D”: we bought technology, the lens is a rather complex object … For us, the low-tech approach is a transition between our current technologies, which are complex, polluting and unsustainable, and those of a future where we would use objects that are sober, repairable and that enable conviviality and equity.” Philippe Blanc, Research Director, Centre O.I.E.

Following this educational activity, the students organized a demonstration day open to all, on May 3, in the Parc des Bouillides near the Pierre Laffitte campus of Mines Paris – PSL in Sophia Antipolis. The aim of the demonstration was to shed light on the solar cookers and the operation of the concentrating furnace, capable of melting glass at temperatures of over 1000°C.

A practical demonstration of the Lytefire solar food oven was also given, providing a tangible illustration of a credible, sustainable alternative to fossil fuels.

Table glass, window glass, glass wool or spectacle glass: all glass has to pass through a furnace of over 1000°C in order to melt it. Typically, this stage is carried out by a gas or electric furnace, which maintains a glass bath at high temperature. The glass was then cast, and the shaping stages determined its future usefulness.

So, how were these steps achieved using only the sun?

The first step was to concentrate the sun’s energy into a small spot, thus achieving the high temperatures required. To concentrate these rays, the students used a Fresnel lens. This produced a power equivalent to that of over “3,000 suns”, illuminating the crucible placed at the focal point of the lens.

The furnace is in fact in two parts: the crucible in which the raw material (cullet, white sand, soda, lime, etc.) is placed, and the enclosure that houses it all. The crucible, made of alumina and insulated from the outside by refractory bricks, can withstand high temperatures and therefore house the glass melting process in complete peace of mind. The role of the enclosure is crucial: it isolates the crucible from the ambient air and acts as a black body, sequestering incoming solar energy and “re-radiating” it in infra-red wavelengths.

In addition to melting the glass, the students built the concentrator so that it could also be used as a solar cooker. The ability to move the oven along the focal axis of the lens enabled the surface of the incoming energy flow to be modified, avoiding flux densities that could burn the food.

At the end of the three-month engineering term, the students prototyped a concentrating solar cooker designed to melt pellets, the raw material used in artisanal glassmaking (like the pellets in a wood-burning stove).

The students also built and tested two types of solar cooker – a box-type oven and a parabolic trough oven – and learned how to cook with them! Solar cookers use solar energy to cook food, offering an ecological and economical alternative to traditional cooking methods. They are ideal for regions with limited access to electricity or fossil fuels.

This cooker is a thermally insulated box with high-temperature-resistant inner walls to minimize heat loss. One transparent side of the box captures sunlight while promoting the greenhouse effect inside. Four reflective panels are arranged at an optimum angle of 60°. They concentrate solar energy, equivalent to the intensity of three suns, enabling internal temperatures of 100°C to 150°C.

The parabolic trough solar cooker is equipped with a parabolic reflector that concentrates sunlight on a focal line, where the cooking vessel is placed. This intense concentration of sunlight on the focal line enables high temperatures to be reached, typically between 200°C and 300°C. These temperatures enable food to be cooked quickly and efficiently.

A big well done to all the students who worked on this UNDERSOLAR project, which perfectly embodies our school’s commitment to responsible innovation. By combining technology with a low-tech approach, their work paves the way for a more sustainable energy transition.

In partnership with the SciDoSol sponsorship chair, the Observation Impacts Énergie center at Mines Paris – PSL is organizing the “Solar Winter School...