Improving eco-design at Mines Paris Research Day: dismantling for less waste

Since 2018, ecosystem and Mines Paris – PSL have been working together to promote the implementation of a circular economy in companies, through training and research initiatives. Indeed, ecosystem is an eco-organization in the Waste Electrical and Electronic Equipment (WEEE ) sector approved by the public authorities on the management of the second and end-of-life of household and professional electrical and electronic equipment (EEE) as well as lamps. The aim of this partnership is to promote training in the skills needed to develop the circular economy, in particular through the training of young professionals as part of the Specialized Master’s (MS) in Environmental Expertise and Sustainable Development (EEDD) in Environmental Engineering and Management (IGE), a course that has been in existence for over thirty years and is adapted to the needs of companies. More recently, this partnership has given rise to the “Circular Economy” certificate, co-organized by ISIGE, the Centre de Gestion Scientifique (CGS), Mines Paris Executive Education and Dauphine University, aimed at experienced professionals. As part of the collaboration for the Specialized Master’s program, the module, co-constructed this year, involved ecosystem, 6 EEE producers who are members of ecosystem, the Fablab and ISIGE teacher-researchers.

In line with the French anti-waste law for a circular economy (Loi AGEC), this 4-week module enables students in ISIGE’s MS EEDD – IGE course to work concretely on improving the environmental impact of various EEE products, by assessing their durability (calculating reparability and recyclability indices) and proposing innovative and realistic ways of changing design models.

Axel Roy, environmental expert and referent for ecosystem’s Ecodesign and Circular Economy Unit: “This is a very practical way of training tomorrow’s professionals, while supporting 6 producers in their ecodesign initiatives, engaging students in proposing relevant actions around recyclability, dismantlability and repairability, and imagining new circular business models. This module enables students to return to practical actions, by delving into the heart of EEE design, to invent the next generation of innovative and sober products.”

Mines Paris – PSL’s Mines Paris Research Day provides an opportunity to discover the cutting-edge research being carried out at the School, facilitating exchanges between researchers, major companies and start-ups. The event highlighted the various possible synergies between science and industry, under the prism of five key challenges: energy transition, data science and AI, cultural and creative industries, mobility of the future, and responsible resource management.

The 2024 edition, held in Paris on July 2, was an opportunity for the team behind this eco-design teaching module, made up of ISIGE – Mines Paris PSL and ecosystem, to share this collaborative project at the heart of the challenge of improving the environmental footprint of industrial products.

Over a four-week period, working with six producers of EEE products, supervised by ISIGE’s teacher-researchers and supported by ecosystem, students are immersed in a process that goes from analysis of the dismantling of these products to modeling and proposing solutions, enabling them to move from theory to practice and actively contribute to improving the sustainability of these products in exchange with the producers.

The first week of the module is devoted to understanding and analyzing the products with the producers. At the heart of this week is the precise dismantling, piece by piece, of EEE equipment supplied by Devialet, Dyson, LG Electronics, Legrand, Lunii, and TRILUX. The students work in close collaboration with ecosystem experts. Together, they evaluate the equipment’s repairability and recyclability indicators. The analyses are aimed at formulating practical recommendations for improving the environmental footprint of equipment.

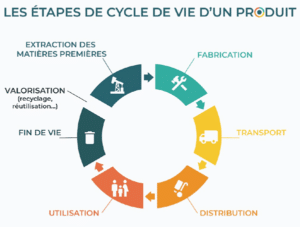

During the following two weeks, MS students model the value chain of various everyday consumer products (refrigerators, tablets, etc.) based on an analysis of their complete life cycle, and calculate their environmental impact using a multi-criteria approach.

The final week is dedicated to proposing practical and realistic solutions for improving the eco-design of the products dismantled and studied in week 1. The students devise new, circular business models, and draw up very concrete recommendations for improving product sustainability and their environmental footprint, which they present to the various producers.

Louise Charles, who graduated in 2023 with a degree in Electrical Engineering, continued her studies by joining the MS program following her graduation. Already very interested in environmental issues, she aspired to work in this field, without any clear idea at the outset of the career she wanted to pursue. Choosing this MS was a way for her to explore various subjects and project herself into different potential sectors. This specialized training opened the door to specific jobs in the environmental field, reinforcing the relevance of her academic and professional career path.

“This project, which is in line with the circular economy, is very instructive and enabled us to grasp the challenges of eco-design and the balance between environmental ambitions and technical constraints. I really liked the format proposed by ISIGE and ecosystem. The dismantling of the equipment was an opportunity for everyone to come to grips with the issues of repairability and recyclability. […] The feedback to the companies was also very much appreciated by the group. Although initially a little skeptical about our added value to product analysis, we were able to provide them with concrete solutions for improving their product.”

The project is perfectly in line with contemporary sustainability issues, as promoted by the AGEC law, which aims to accelerate change in production and consumption models in order to limit waste and preserve natural resources, biodiversity and the climate. It is also in line with the European Union’s Ecodesign Directive on the electrical consumption of products, which aims to reduce the consumption of electrical and electronic appliances through better design. These regulations encourage manufacturers to take an interest in the durability of their products, notably by optimizing their reparability and recyclability.

“Ecodesign in Reality” demonstrates the importance of the alliance between science and industry. By combining theoretical knowledge with practical applications, the project paves the way for more sustainable products and more responsible industrial practices. The promising results of this module testify to the ability of future generations of engineers to meet environmental challenges.